We wind the large toroid by hand, (photo example of the table set up is in the Book), as no commercial winding machine can get into our stacked cores. We mylar tape and epoxy each winding, this stops the buzzing and movement of the windings so eliminating early failure due to internal vibration and the consequent shorting out.

We test each winding for correct turns etc, we wind a low count single primary core, about 50mm/2, better cooling abilities, we bench test it and test the secondary and amend the primary turn to get what we want.

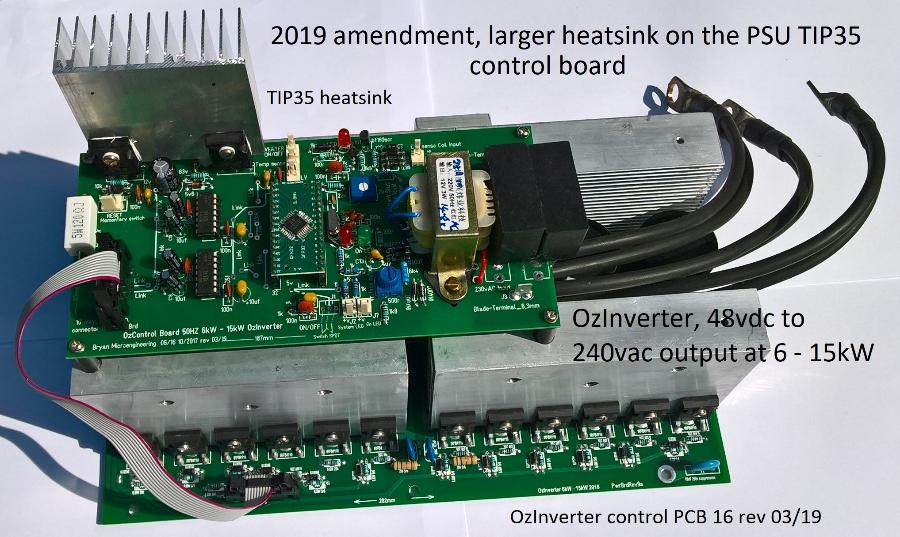

The New Power Board, the New OzControl board and OzCooling board, SEE PHOTOS ABOVE, are designed for real harsh environments and manufactured with large tracks, large pads, to stop substrate separation and importantly all components are through hole type, so in the field repairs are relatively easy. Especially if you have insect/moisture infestation. We also put all component values on the boards silk screen, so its "painting by numbers", and therefore very easy to repair without dragging out paperwork to find out what goes where.

We use the 8010 SMD chip, (the only SMD component) and run at 23.4KHz modulation frequency. We have several methods of soft starting the large toroid and this is a key issue. We have also all the normal things, like overtemp shut down and auto restart, etc and can be 50Hz or 60Hz.

They will take 6kW and up to 15kw but cooling is the key here, again its in the book with the OzCooling circuit and Board.

If you follow the book’s methods, you end up with a robust, simple, stonking big, serious Power Inverter, and all at a very reasonable Price, around $600.

Amendments 2019.

The 2 TIP35's that are the voltage supply for the 15v FET drivers 2110, and the 5v +- for the 8010 SMD chip, get warm, please fit a good heatsink as in the Photo.

OzControl board 16 rev 03/19 and onward has the TIP's aligned and modified to allow for a larger heatsink. ..... see below photo.